RPS

RUNNER PRODUCTION SYSTEM

EASO applies “Lean Operating System” since 2015 by implementing Toyota Lean Production (TPS) concept with EASO’s enterprise culture, green technology and innovation concepts to make it conforming to EASO’s development direction. EASO’s lean production system relies on four key production capabilities: Injection Molding Capability, Finish Treatment Capability, Metal Forming Capability and Automatic Assembly Capability.The lean production greatly improves the production efficiency by shortening the operation path, accelerating the working flow, establishing poka-yoke system and independent operation system to achieve “smaller input but greater output”.

RPS

PRODUCTION

SYSTEM

Plastic

01

Manufacturing Capability

There are also automatic assembly lines for shower and faucet waterway.

Comprehensive quality control with air test, under-water test, functional test, flow test, Poka Yoke test, etc.

Advanced equipment in the process: auto screw driver, auto nut machine, integrated assembly machine, ATEQ air tester, water dryer, ultrasonic welder, hot plate welder, clam shell welder, etc.

Learning from TPS (Toyota Production System) concept, work stations support more flexible and customized production orders.

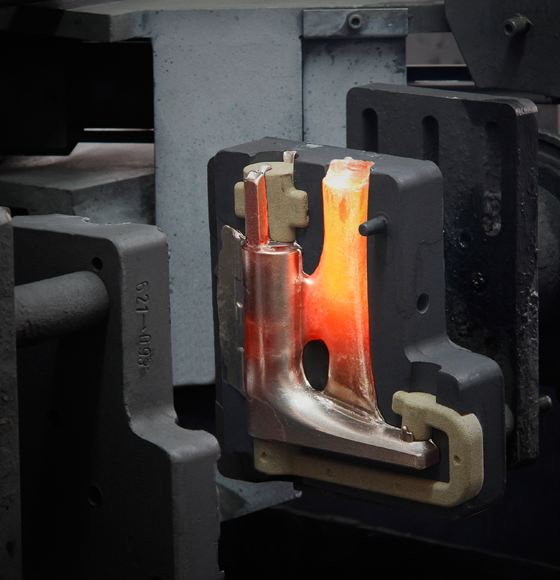

Metal-Manufacturing Capability

02

-

The product ranges from kitchen faucet, basin faucet, thermostatic shower faucet, bathtub faucet, sewage valve, safety valve, angle valve, washing faucet, etc.Comprehensive quality control with air test, under-water test, functional test, flow test, Poka Yoke test, etc. Advanced equipment in the process: auto screw driver, auto nut machine, integrated assembly machine, ATEQ air tester, pre-valve & after-valve tester, water tester, pad printer, laser printer, valve auto assembler, etc. Learning from TPS (Toyota Production System) concept, work stations support more flexible and customized production orders.

-

Filter + Electronic Strength

03

Manufacturing Capability

The professional pre-filter and electronic faucet lines include intelligent toilet pre-filter, shower pre-filter, water heater pre-filter, electronic filter faucet, instant heating faucet, sensor faucet, etc.

Comprehensive quality control with air & water test, functional test, aging test, electronic display test, flow test, Poka Yoke test, etc.

Advanced equipment in the process: auto screw driver, auto nut machine, integrated assembly machine, ATEQ air tester, pre-valve & after-valve tester, thermostatic water tester, pad printer, laser printer, etc.

Learning from TPS (Toyota Production System) concept, work stations support more flexible and customized production orders.